Home » Oil & Gas Pipeline Safety: Microsoft IoT Solutions That Prevent Costly Downtime

Pipeline failures can be expensive and harmful to the environment. Companies are using IoT applications in the oil and gas industry to prevent these breakdowns and stay ahead of problems.

When a pipeline breaks down, it not just causes a delay but brings big problems. Here we highlight some of the losses oil and gas companies face when pipelines fail:

In simple words, pipeline failures can hit a company’s overall reputation, hurt the environment, and cause serious legal trouble.

Old ways of checking pipelines, like manual inspections are slow and often miss early warning signs. But IoT solutions for oil and gas industry give companies a smarter way to monitor pipelines in real time.

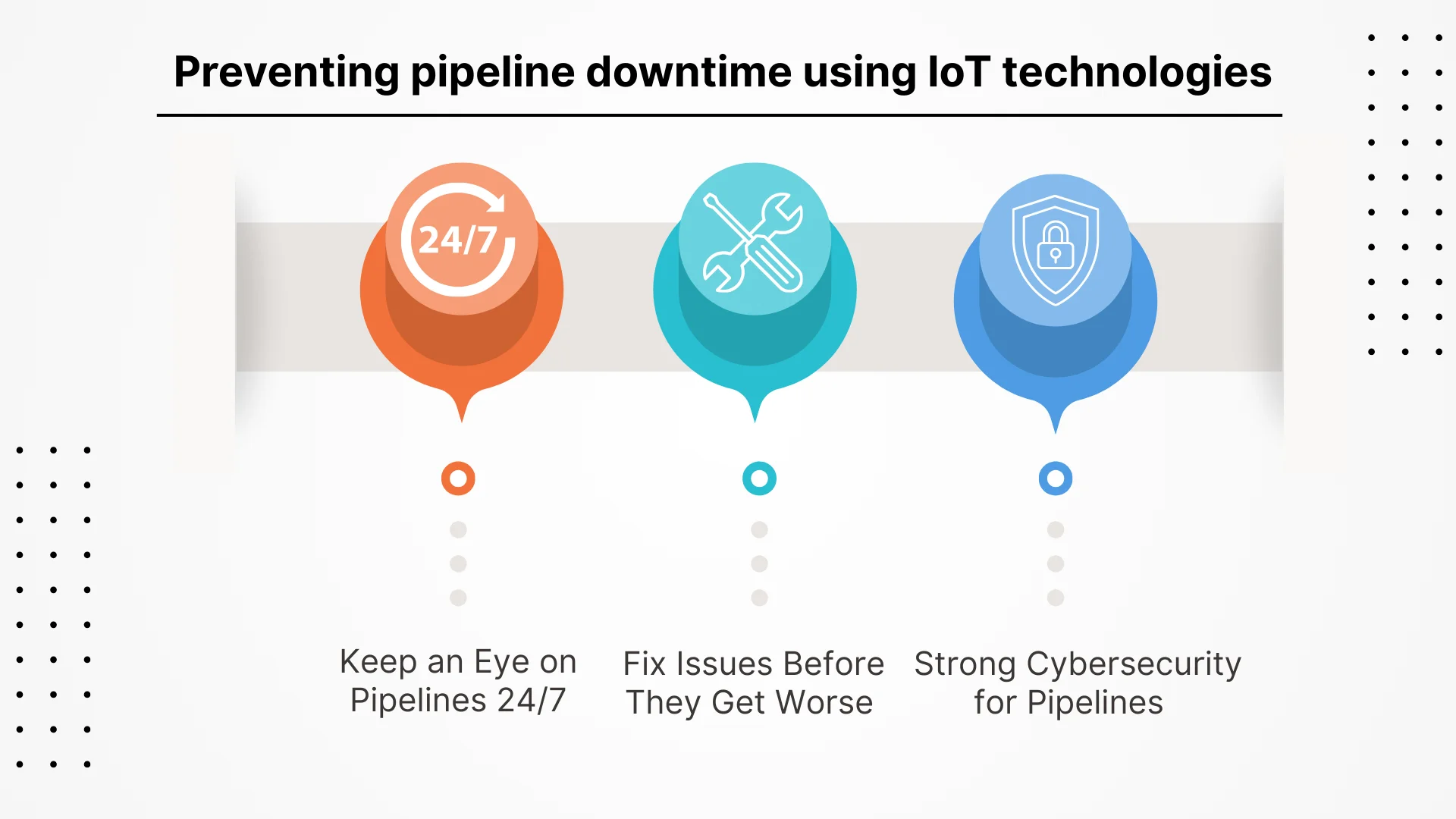

Here’s how IoT use cases in oil and gas industry are helping:

Next, we will explore the specific Microsoft IoT tools that are enabling oil and gas companies to avoid pipeline failures and reduce expensive downtime.

If you want to save money, cut downtime, and keep your pipelines safe, here’s how Microsoft IoT can make a difference.

Pipelines work all day and night—so your monitoring system should too. With real-time monitoring of pipelines using Azure IoT, smart sensors track things like pressure, temperature, and flow rates all the time. If something unusual happens, the system sends an alert right away.

You don’t have to wait for routine checks to find problems. You get alerts instantly—before small issues become big (and expensive) ones.

Let’s say a pipeline’s pressure rises suddenly. Instead of finding out days later, Azure IoT alerts your team instantly so that you can fix the issue as earlier as possible avoiding any major issue.

What if you could know when a part of your pipeline is about to fail? With Microsoft’s predictive maintenance, you can. The system studies past data and predicts when something is likely to break which means no more surprise breakdowns or last-minute repairs. You stay ahead of problems and keep your pipelines running smoothly.

For Example: If a pump is wearing out, the system spots early warning signs. You can replace it during regular maintenance instead of waiting for it to fail—saving time, money, and avoiding shutdowns.

Hacking is a real threat to oil and gas systems. Microsoft Defender for IoT helps protect pipelines from these digital attacks. Microsoft Defender for IoT secure oil and gas pipelines by detecting suspicious activity and blocking unauthorized access.

Let’s say, if someone tries to hack your pipeline’s monitoring system, Defender for IoT blocks the attempt and alerts your team—keeping your data safe and your systems working.

Let’s face it—fixing problems after they happen is expensive and stressful. That’s why successful oil and gas companies use Microsoft IoT to:

Now let’s just explore real-world examples of how Microsoft IoT is helping oil and gas companies avoid failures and boost efficiency—and how you can do the same.

Sometimes a small mistake in the system can ripple through the entire operation. A broken pipeline or a missed warning could mean millions in repairs, damage to the environment, and safety risks for workers.

That’s why leading companies are using IoT in the oil and gas industry to predict problems, improve efficiency, and stay safe.

Let’s look at how real companies are using Microsoft IoT solutions to avoid failures and increase productivity—and how you can too.

The Problem:

Running big mining and oil sites is hard. You need to watch worker safety, energy use, and machines, but old systems cannot provide quick updates or fast alerts during emergencies.

The Solution:

Schneider Electric adopted IoT for oil and gas using Microsoft Azure IoT to connect and monitor their operations. With using these tools, they can:

Keep Workers Safe: IoT sensors track underground conditions and send instant alerts at emergencies.

Track Resources: Digital systems follow ore from extraction to delivery, improving supply chain accuracy.

Manage Energy Better: IoT energy management reduces power waste by monitoring and controlling energy use.

The Result?

The Problem:

Freeport-McMoRan, a major natural resource company, had too much data from their operations. They needed a way to turn their raw data into useful insights without rebuilding their entire system.

The Solution:

They used the Accenture Hybrid Cloud Solution for Microsoft Azure to create an Industrial Internet of Things (IIoT) platform. This platform allows them to:

The Result?

The Problem:

XTO Energy, a division of ExxonMobil, aimed to boost oil well efficiency in the Permian Basin. But their slow data collection methods made it hard to foresee future drilling needs.

The Solution:

They integrated Microsoft Azure IoT technologies with Microsoft Dynamics 365, allowing them to:

The Result?

Get free Consultation and let us know your project idea to turn into an amazing digital product.

The oil and gas industry faces big problems—pipeline failures, safety risks, and cyberattacks. To stay safe and ahead, many companies are using Microsoft IoT solutions. These smart tools help monitor pipelines, prevent costly breakdowns, and keep important systems safe—all while making work easier and faster.

Let’s see how Microsoft IoT technology is helping oil and gas companies avoid problems and work better.

The oil and gas industry faces big problems—pipeline failures, safety risks, and cyberattacks. To stay safe and ahead, many companies are using Microsoft IoT solutions. These smart tools help monitor pipelines, prevent costly breakdowns, and keep important systems safe—all while making work easier and faster.

Let’s see how Microsoft IoT technology is helping oil and gas companies avoid problems and work better.

Share your project idea with us. Together, we’ll transform your vision into an exceptional digital product!

The oil and gas industry can’t afford mistakes. Microsoft IoT solutions make it easier to prevent pipeline failures, protect systems from cyberattacks, and improve safety. With real-time monitoring through Azure IoT and strong security from Microsoft Defender for IoT, companies can avoid major problems and save on repair costs. As technology grows, these solutions are not just helpful—they are necessary. If you want to lower costs and work more efficiently, check out our related blog, How to Reduce High Operational Costs with IoT Solutions in Oil and Gas Industry? to learn how IoT can help your business save money and stay ahead.

It’s a system that uses smart devices to track pipeline conditions in real time, helping prevent leaks and breakdowns.

It constantly checks for problems, spots issues early, and sends alerts to prevent accidents.

It studies sensor data to find patterns, predict failures, and suggest fixes.

It sends instant alerts when something goes wrong, so you can respond quickly.

It improves safety, reduces downtime, cuts maintenance costs, and helps follow safety rules.

It allows repairs based on real-time data instead of fixed schedules, saving time and money.

Yes, it has strong security features like encryption and access controls to protect data.

It can be expensive to start, hard to connect with old systems, and managing data can be challenging.

Sensors collect data non-stop and send it immediately to a central system for checking.

More use of AI, better safety, and smarter data analysis to improve operations.

Most enterprises did not choose to be here. Core systems were built to be stable, not adaptable. Over time, layers of customization, integrations, and workarounds turned reliability into rigidity. Today, every new digital initiative feels harder than it should be.

Recent industry data shows that most enterprises now treat Azure Migration Services as a core part of their IT modernization plans rather than a one time project. Businesses are actively prioritizing cloud migration to Azure to improve reliability, security, and long term cost control.

In 2026, moving workloads to Azure cloud migration is not just about transferring data. It’s about making the whole process smarter, more automatic, and easier to manage while keeping compliance and security tight.

Founder and CEO

Chief Sales Officer